Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Contains: Sulfur (S) / Selenium (Se)

May React With: Copper (Cu), Lead (Pb), and Silver (Ag)

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008), Rod (-0576), Stringer (-0507, -0107, -0272), and Ribbon (-0401)

Detailed Information

About 000126 Sheet Glass

Cold Characteristics

Color variations common from minty-pastel to vibrant yellow-green.

Working Notes

Lighter coloration matures and becomes consistent to target upon firing.

A sulfur glass. May react with lead and copper glasses to create dark interface (lead sulfide, copper sulfide).

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

About 000126 Frit

Working Notes

Coarse Frit

Medium Frit

Fine Frit

Powder

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

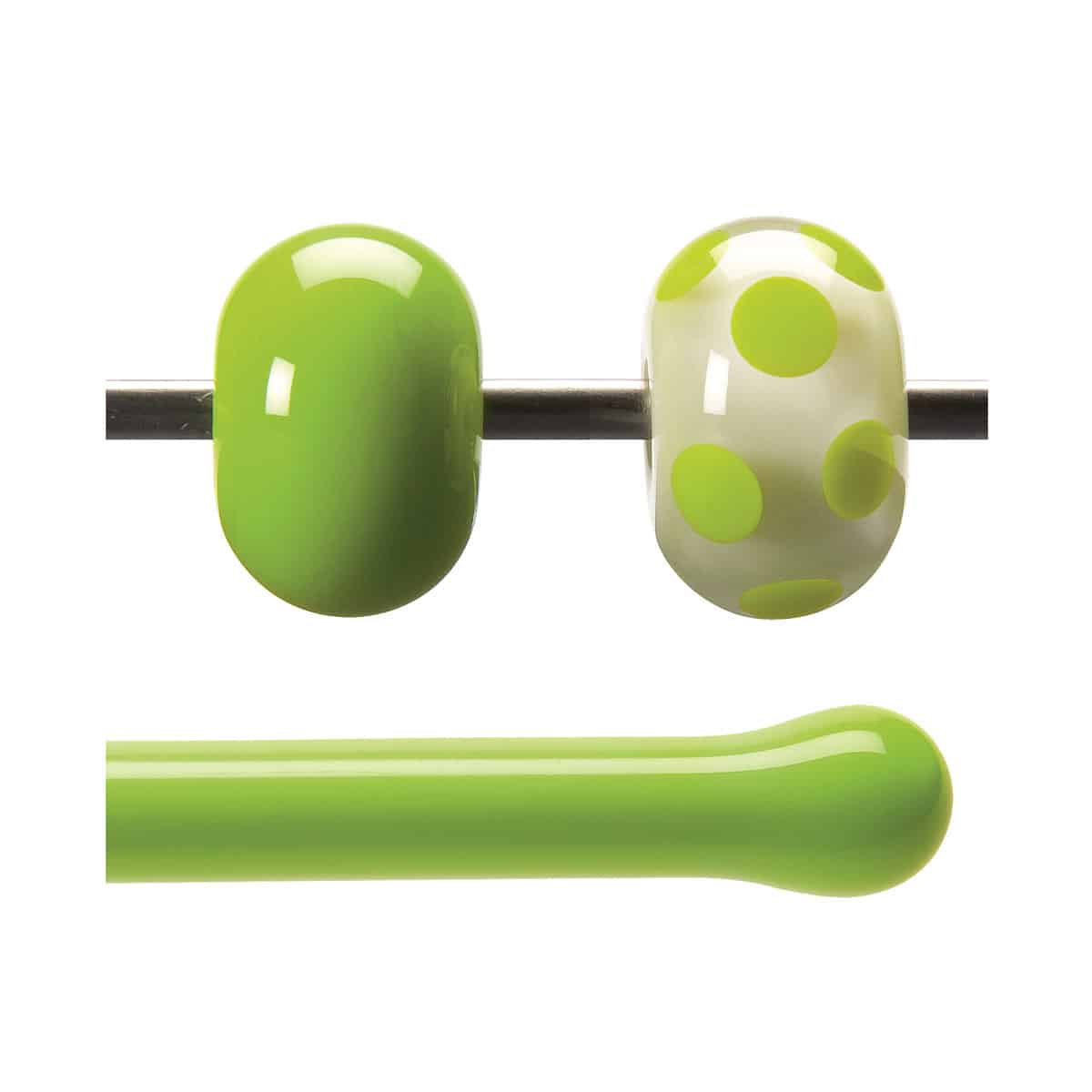

About 000126 Rod

Cold Characteristics

Slight variations from one production run to another.

Working Notes

Torch: Lighter color and greater opacity than in sheet glass form. Keep it a bright chartreuse by working with a neutral to oxidizing flame atmosphere. Can turn gray in reduction.

Kiln: Lighter color and greater opacity than in sheet glass form.

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

About 000126 Stringer

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

About 000126 Ribbon

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.