Overview

Reactive Potential

Non-reactive. Neutral.

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008), Ribbon (-0401), Confetti (-0004) and Billet (-0065)

Detailed Information

About 000113 Sheet Glass

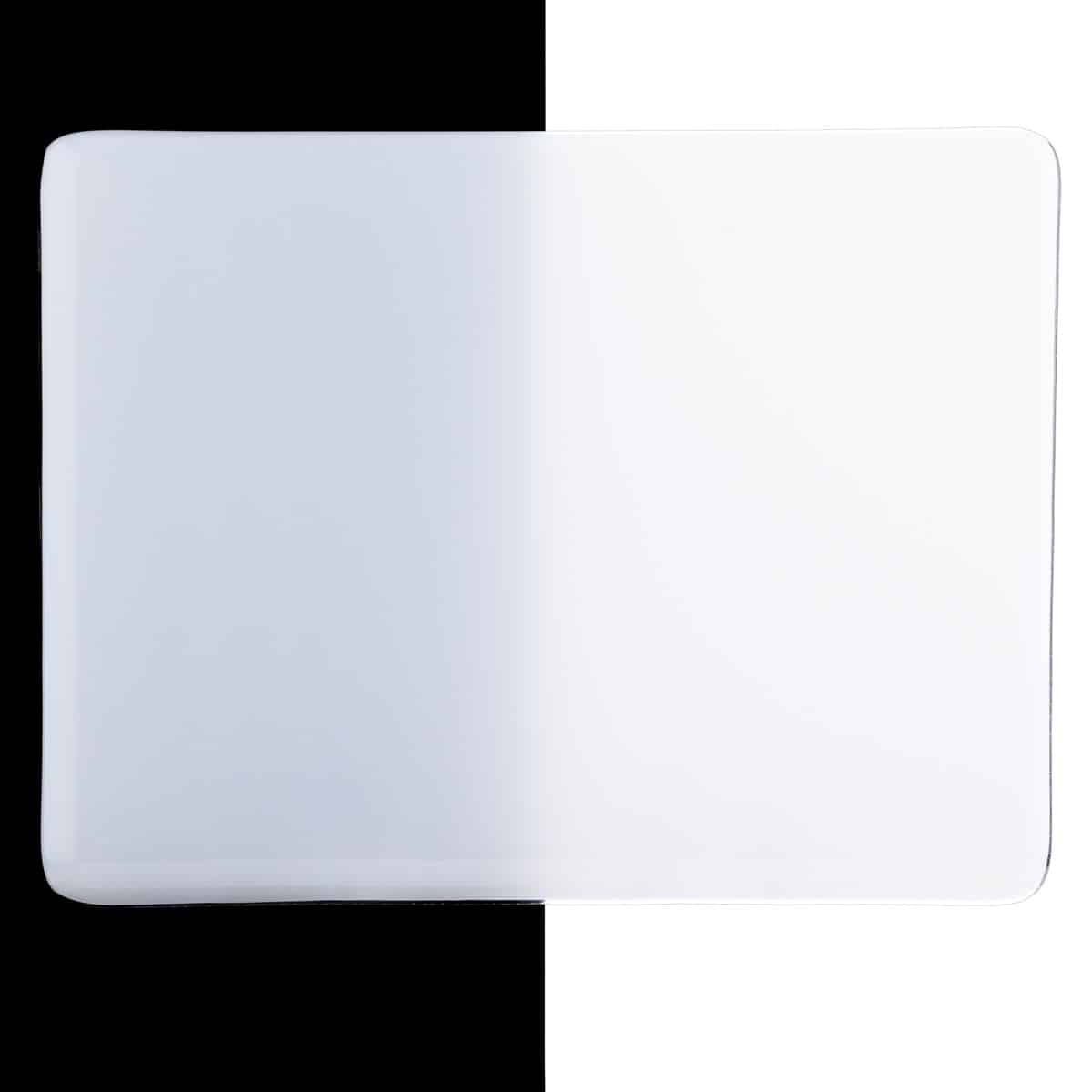

Cold Characteristics

Partly transparent. Slight dappling of color.

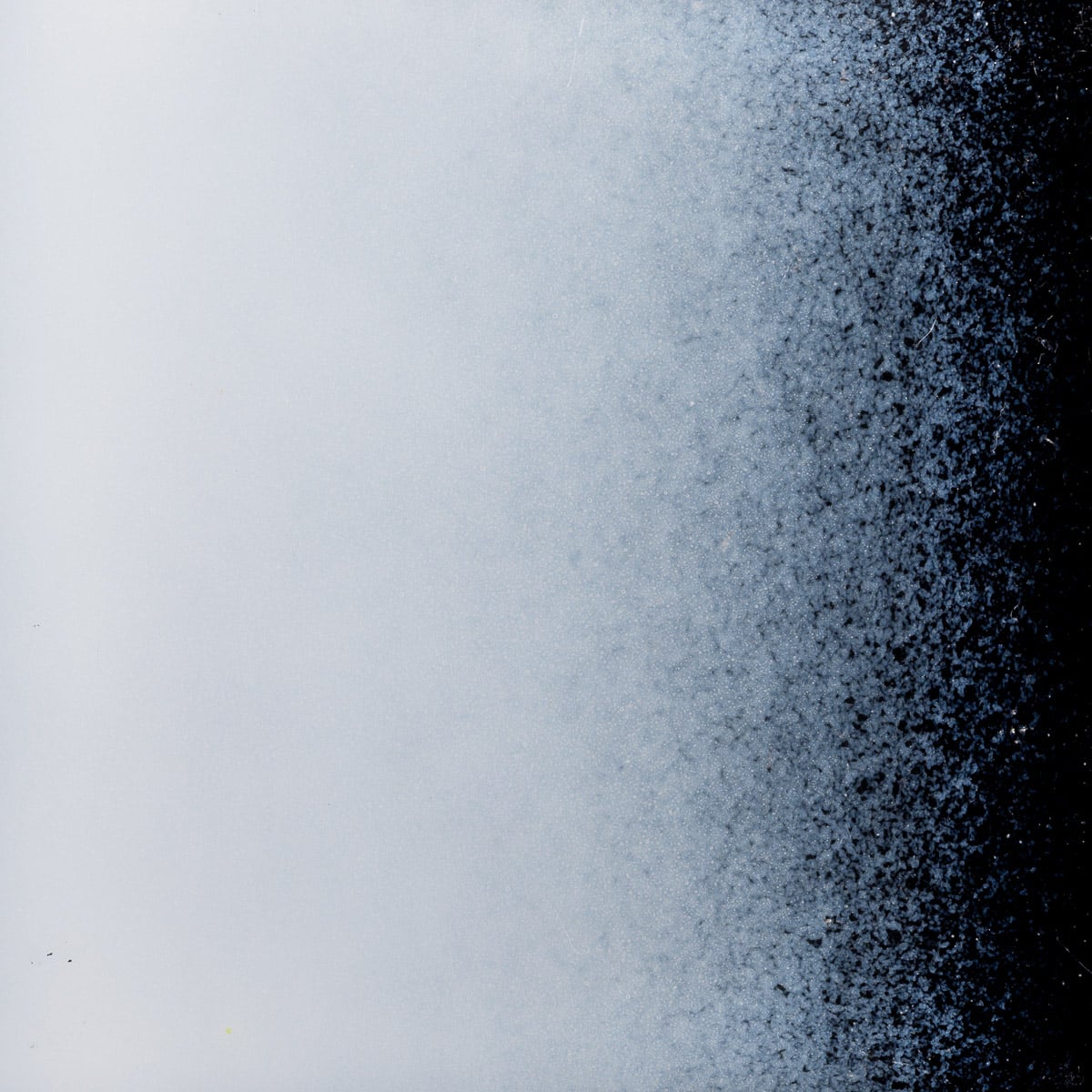

Working Notes

Opalizes upon firing. Slight dappling apparent in transmitted light.

Bullseye Compatible.

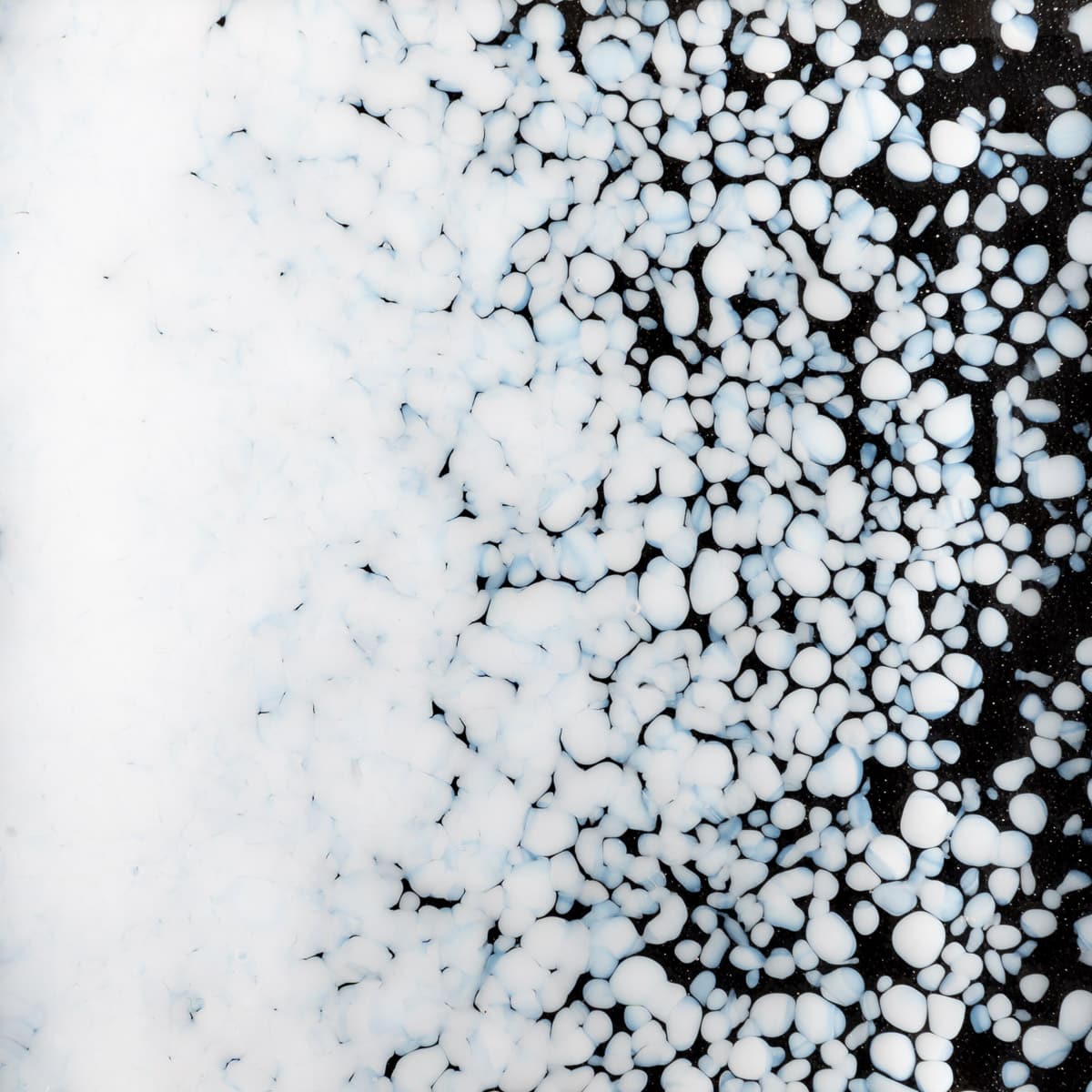

About 000113 Frit

Working Notes

See sheet glass notes about this style.

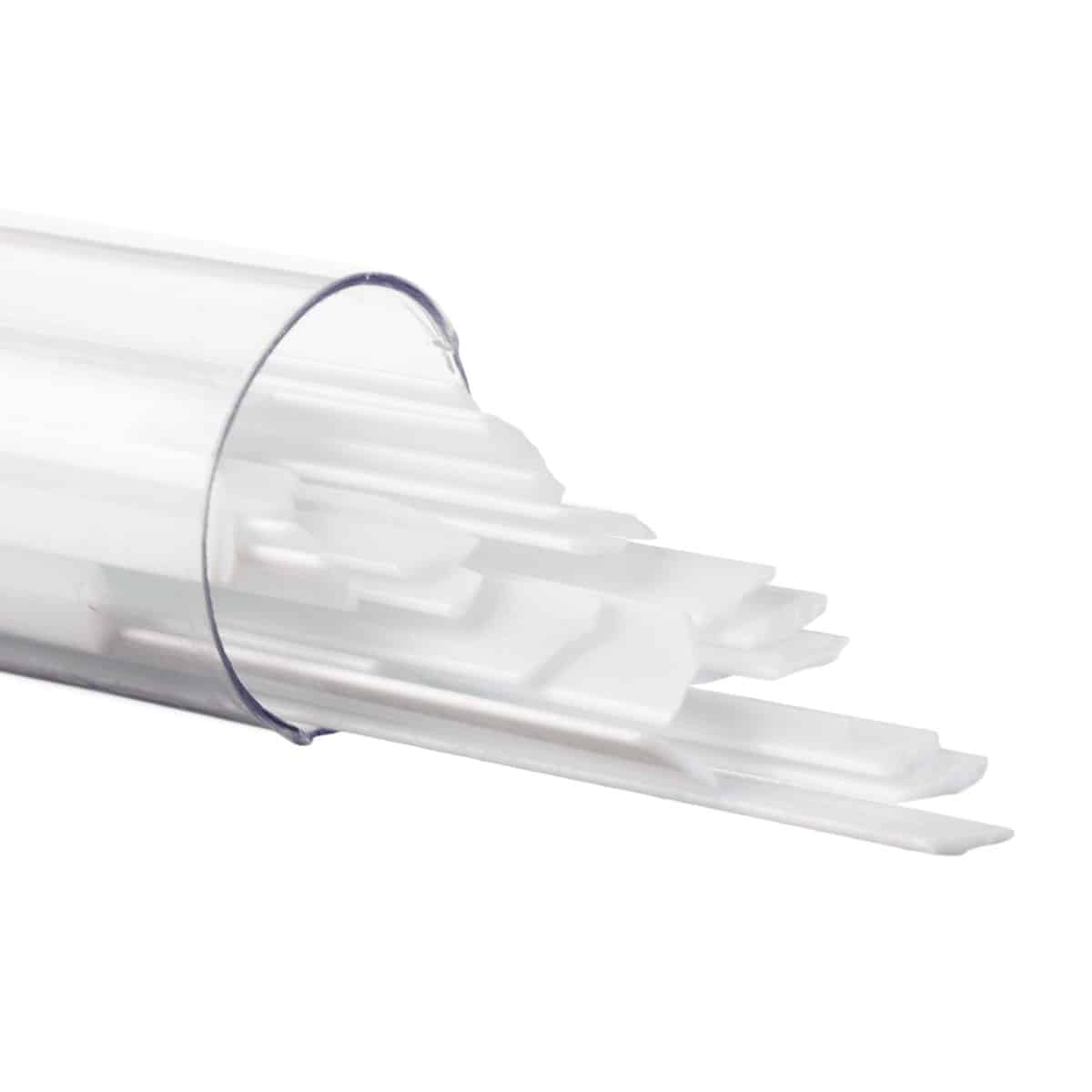

About 000113 Stringer

Working Notes

As of Spring 2019, White Opalescent stringer (000113) has been reclassified under Dense White Opalescent (000313). For reactive potential and working notes, please see Dense White Opalescent.

About 000113 Ribbon

Working Notes

See sheet glass notes about this style.

About 000113 Confetti

Working Notes

See sheet glass notes about this style.

About 000113 Billet

Working Notes

See sheet glass notes about this style.