Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Contains: Sulfur (S) / Selenium (Se)

May React With: Copper (Cu), Lead (Pb), and Silver (Ag)

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008), Rod (-0576) and Stringer (-0272, -0107)

Detailed Information

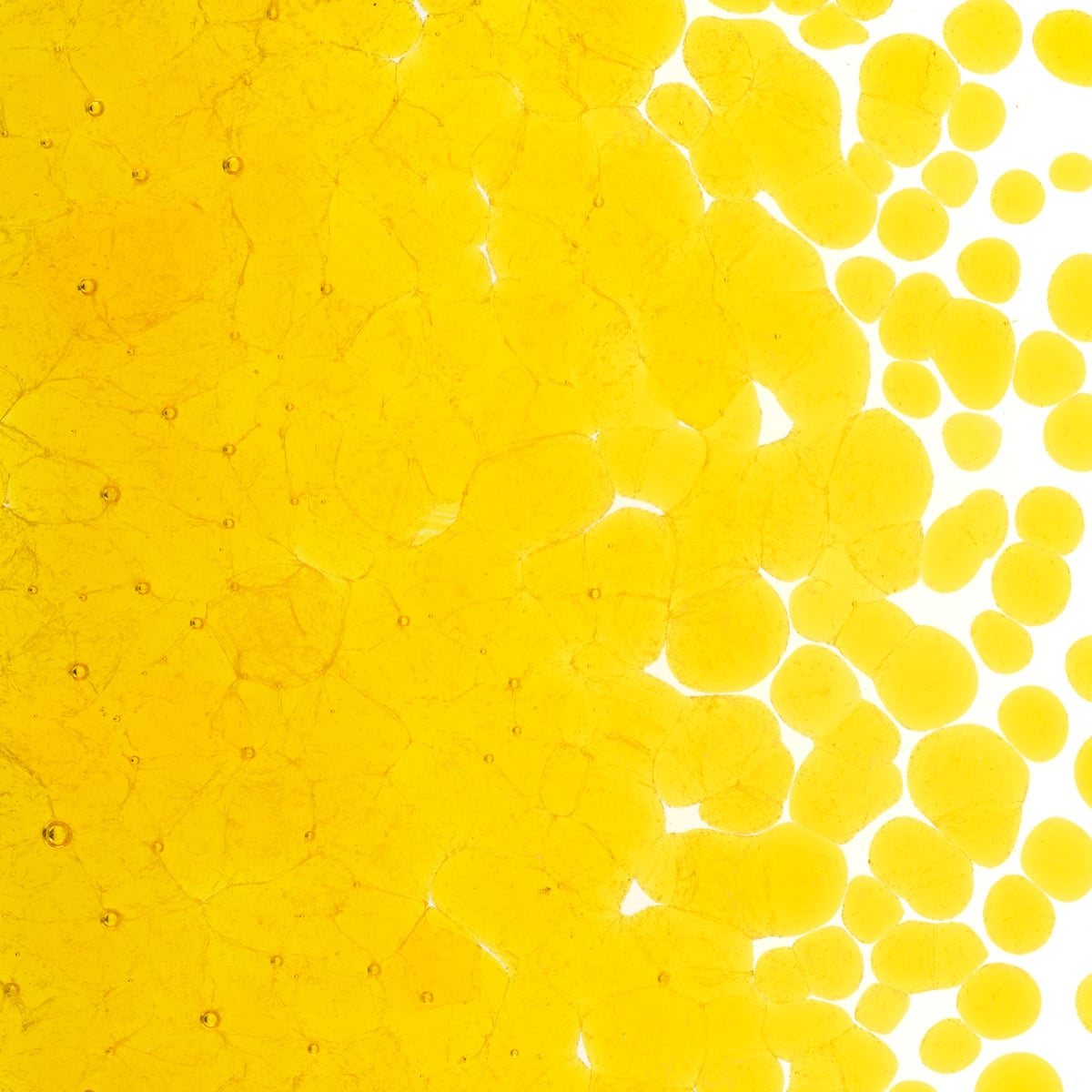

About 001120 Sheet Glass

Cold Characteristics

Consistent color.

Working Notes

A cadmium glass.

This style is not suitable for kilncasting because it can opalize and/or become incompatible when held at high temperatures for an extended period. It may also opalize and/or become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

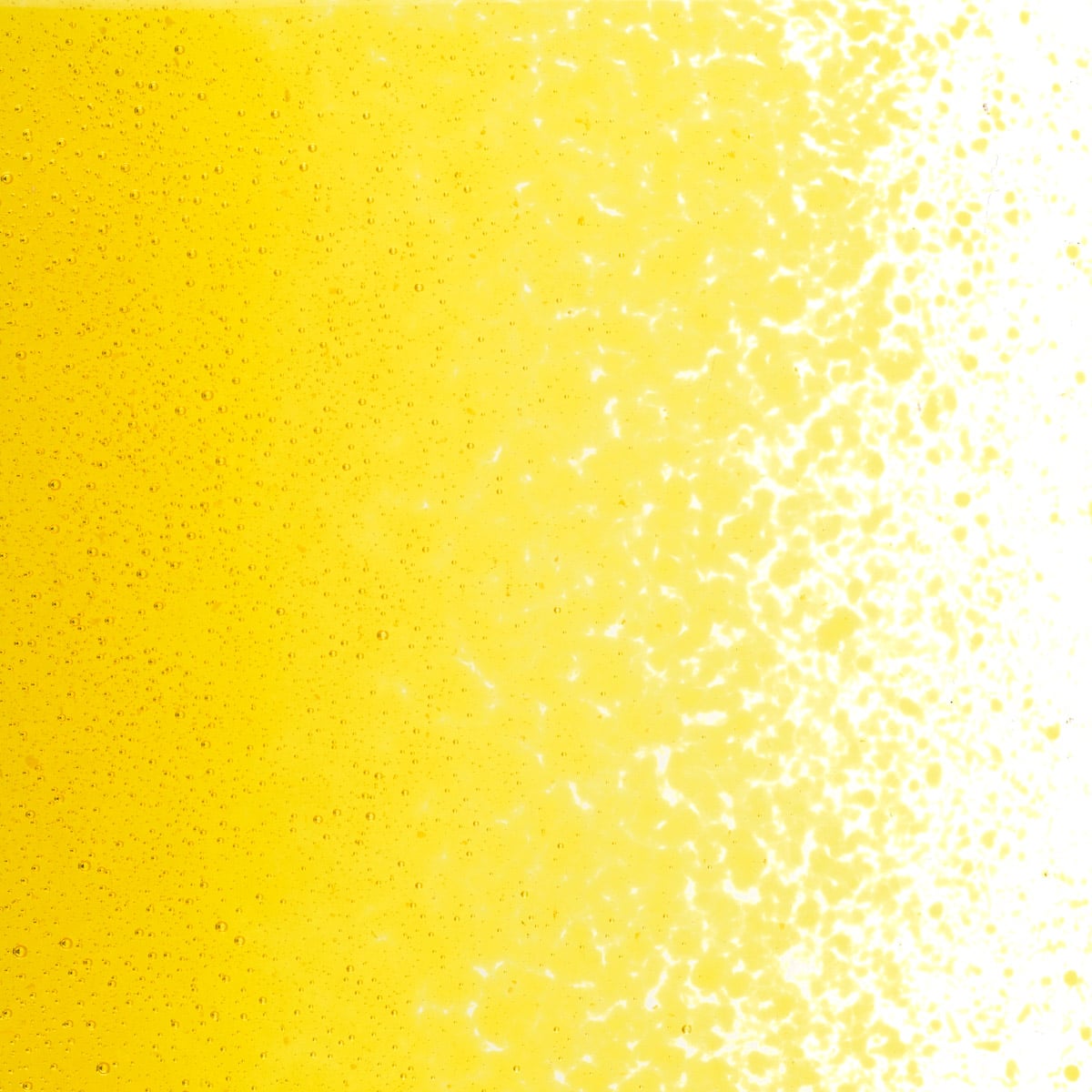

About 001120 Frit

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

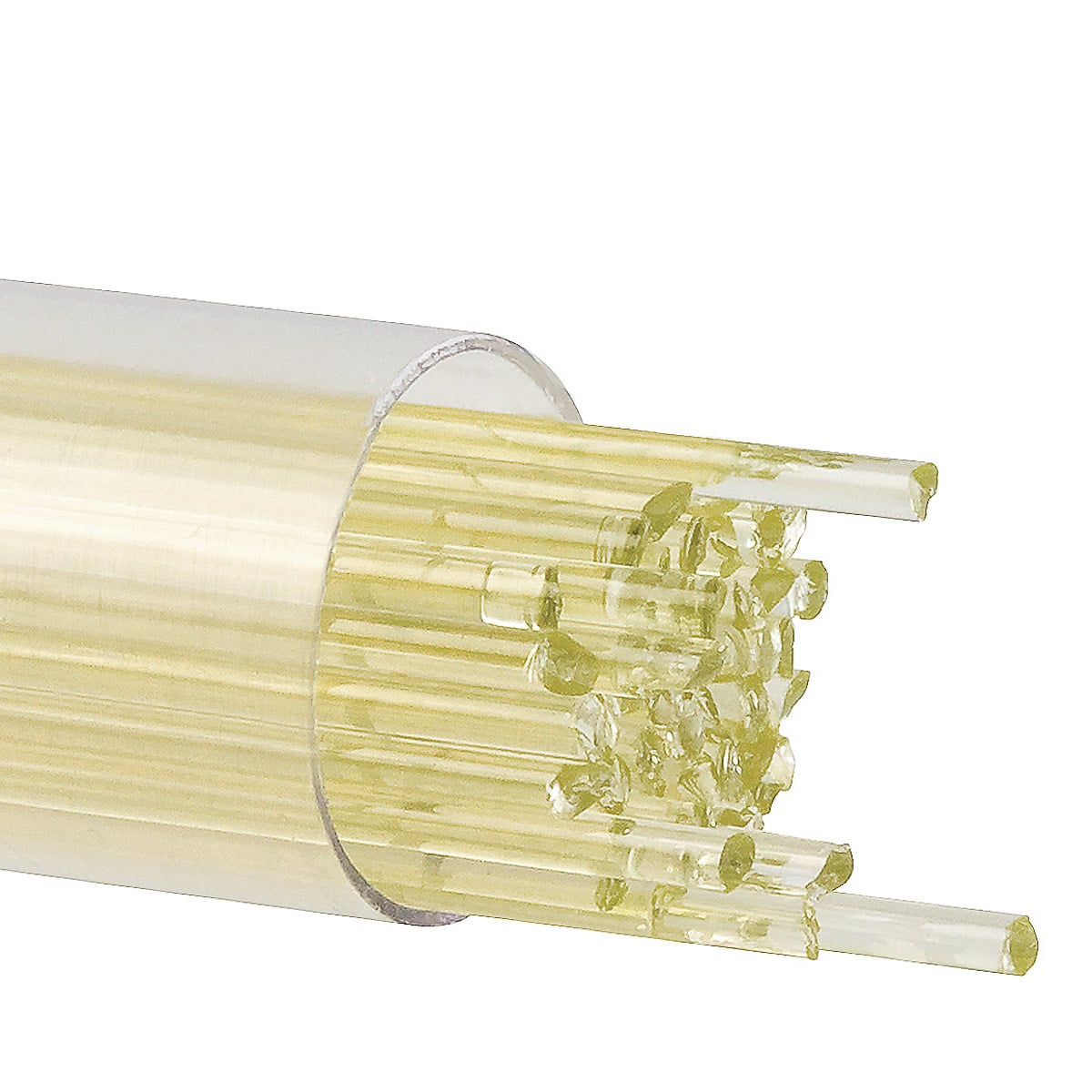

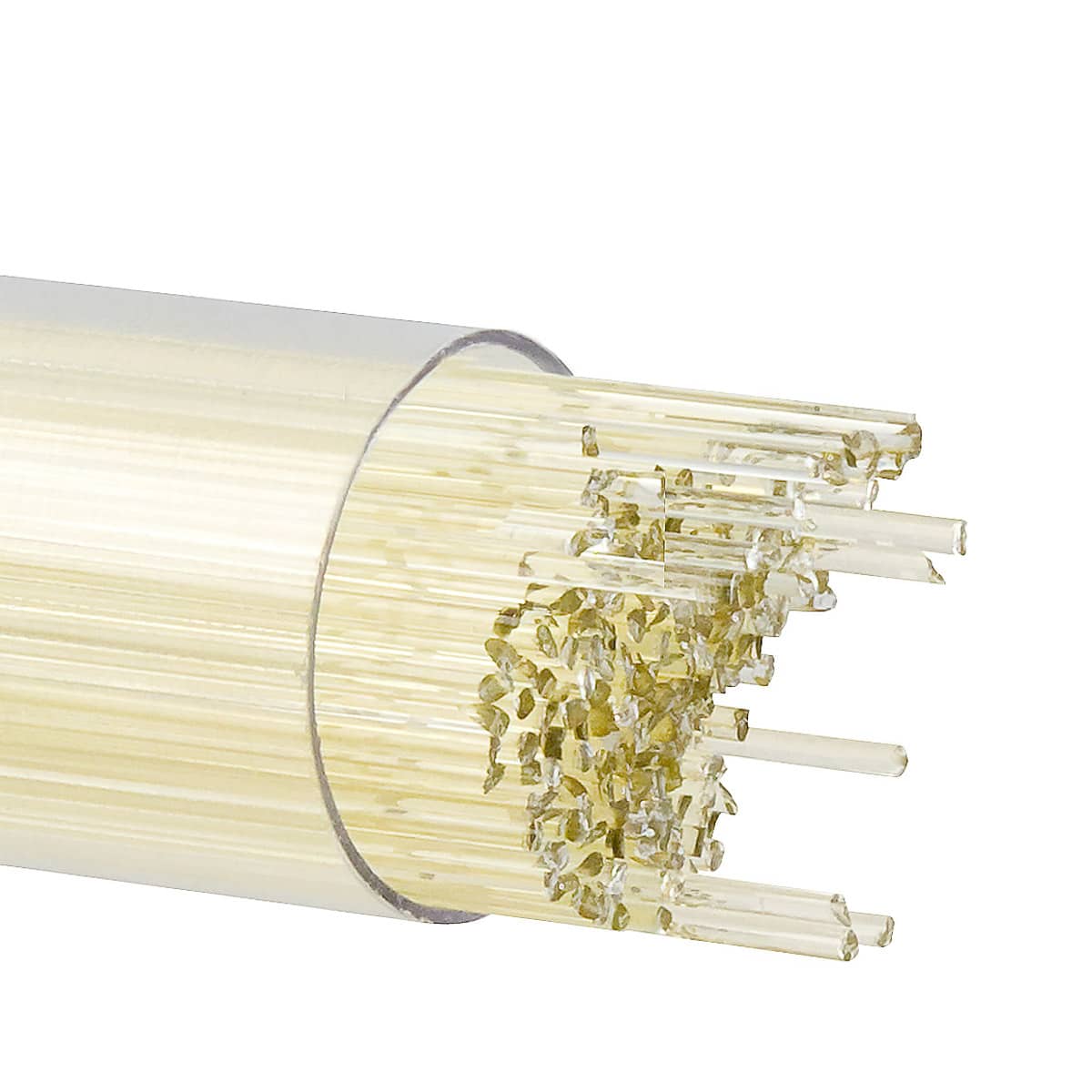

About 001120 Rod

Cold Characteristics

Pale transparent amber, similar to Orange Transparent Rod (001125-0576) and Light Amber Transparent Rod (001437-0576). May have a struck streak of yellow running lengthwise down the rod.

Working Notes

Torch: Yellow color develops in the flame. Keep 001120-0576 transparent by using it in small amounts with minimal heatwork, or consider adding it towards the end of the time in the flame. We advise labeling all striking glasses.

Kiln: This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

About 001120 Stringer

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.