Basic Principles

BUY THE BEST CUTTER YOU CAN AFFORD.

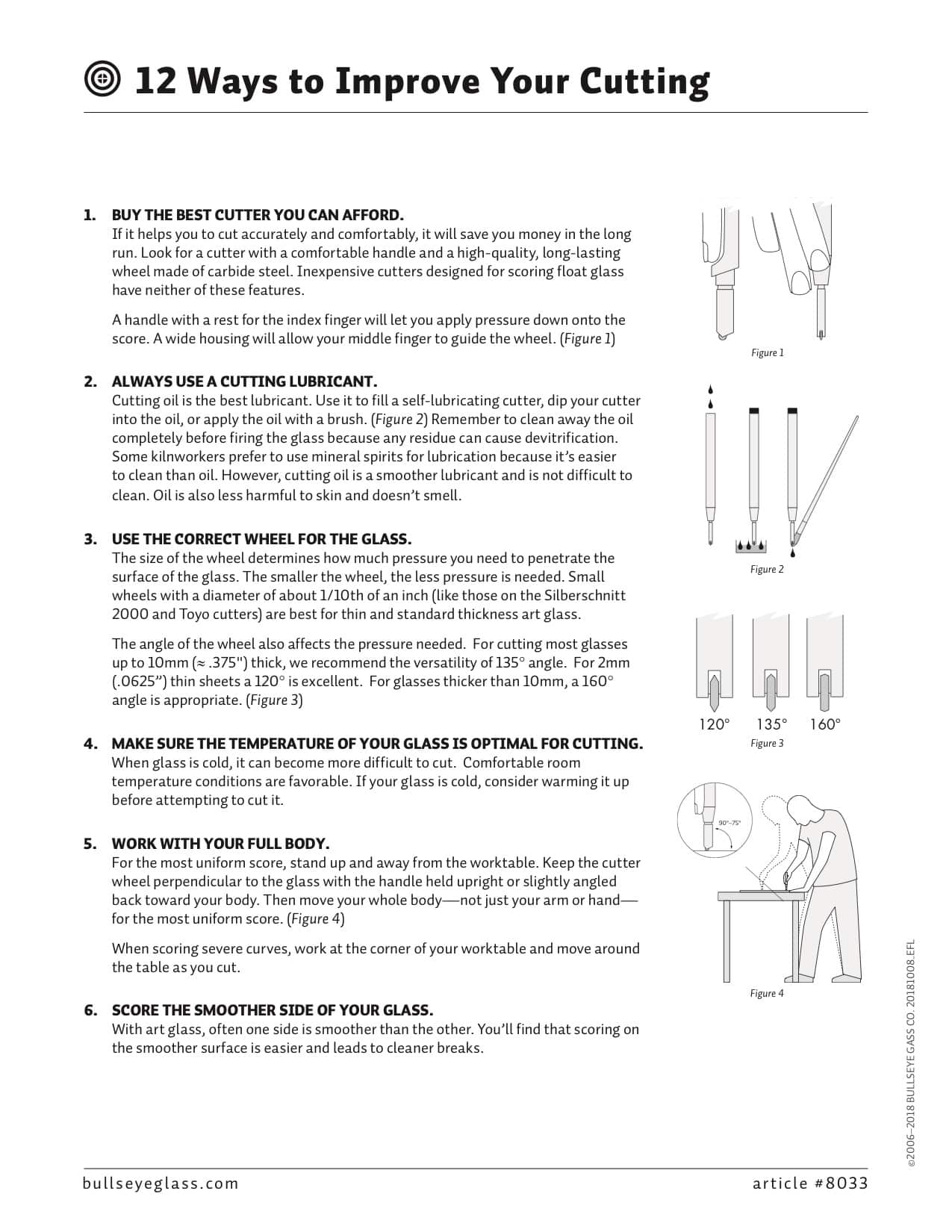

If it helps you to cut accurately and comfortably, it will save you money in the long run. Look for a cutter with a comfortable handle and a high-quality, long-lasting wheel made of carbide steel. Inexpensive cutters designed for scoring float glass have neither of these features. A handle with a rest for the index finger will let you apply pressure down onto the score. A wide housing will allow your middle finger to guide the wheel. (Figure 1)

ALWAYS USE A CUTTING LUBRICANT.

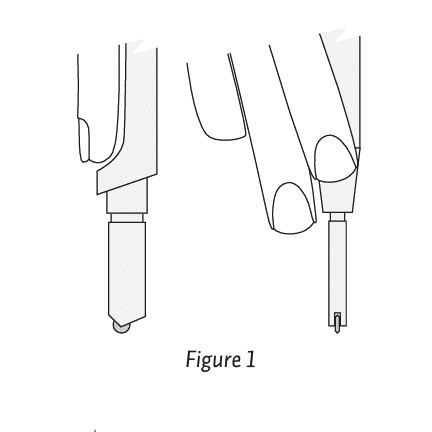

Cutting oil is the best lubricant. Use it to fill a self-lubricating cutter, dip your cutter into the oil, or apply the oil with a brush. (Figure 2) Remember to clean away the oil completely before firing the glass because any residue can cause devitrification. Some kilnworkers prefer to use mineral spirits for lubrication because it’s easier to clean than oil. However, cutting oil is a smoother lubricant and is not difficult to clean. Oil is also less harmful to skin and doesn’t smell.

USE THE CORRECT WHEEL FOR THE GLASS.

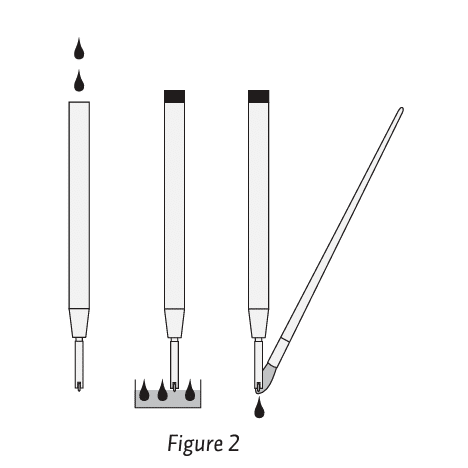

The size of the wheel determines how much pressure you need to penetrate the surface of the glass. The smaller the wheel, the less pressure is needed. Small wheels with a diameter of about 1/10th of an inch (like those on the Silberschnitt 2000 and Toyo cutters) are best for thin and standard thickness art glass. The angle of the wheel also affects the pressure needed. For cutting most glasses up to 10mm (≈ .375″) thick, we recommend the versatility of 135° angle. For 2mm (.0625”) thin sheets a 120° is excellent. For glasses thicker than 10mm, a 160° angle is appropriate. (Figure 3)…

To learn more, download and print the free pdf article, also available for your convenience as part of Bullseye’s TechBook.