Basic Principles

A glass cutter does not saw glass. Rather, its cutting wheel “scores” the glass—creating a shallow fissure as it rolls across the surface. This fissure, or “scoreline,” breaks the surface tension of the glass and allows it to snap when pressure is applied downwards on either side of the fissure. The cleanness of a break is determined by the pressure applied during the score. Too much pressure results in a gritty white scoreline with flaking and chips. Too little pressure can result in a scoreline that is not continuous and may break unpredictably. A good score can be identified by sight. It is uniformly shallow and continuous, without flakes. You can also hear a good score as it happens. The zipping sound it makes is not harsh or grating but satisfyingly uniform and crisp.

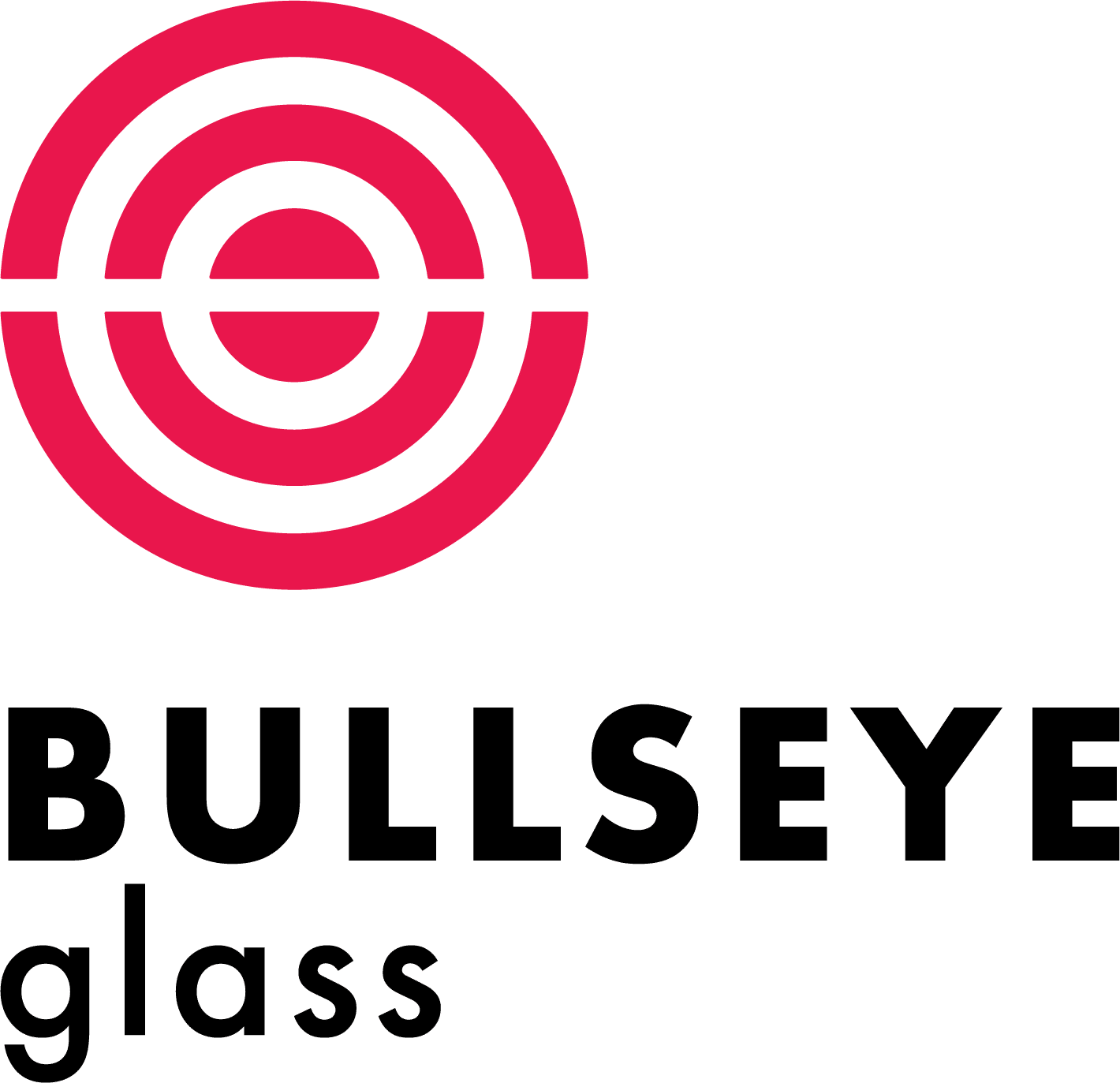

Making the Score

Any position that allows you to exert adequate and even pressure while holding the cutter wheel perpendicular to the glass surface is proper. The cutter may be either pushed or pulled across the surface. Applying even pressure and uniform speed is more important than direction. Score off the edge of the glass. Do not retrace a poor score. This will only cause a gouge in the glass and damage to the cutter wheel…

To learn more, download and print the free pdf article, also available for your convenience as part of Bullseye’s TechBook.