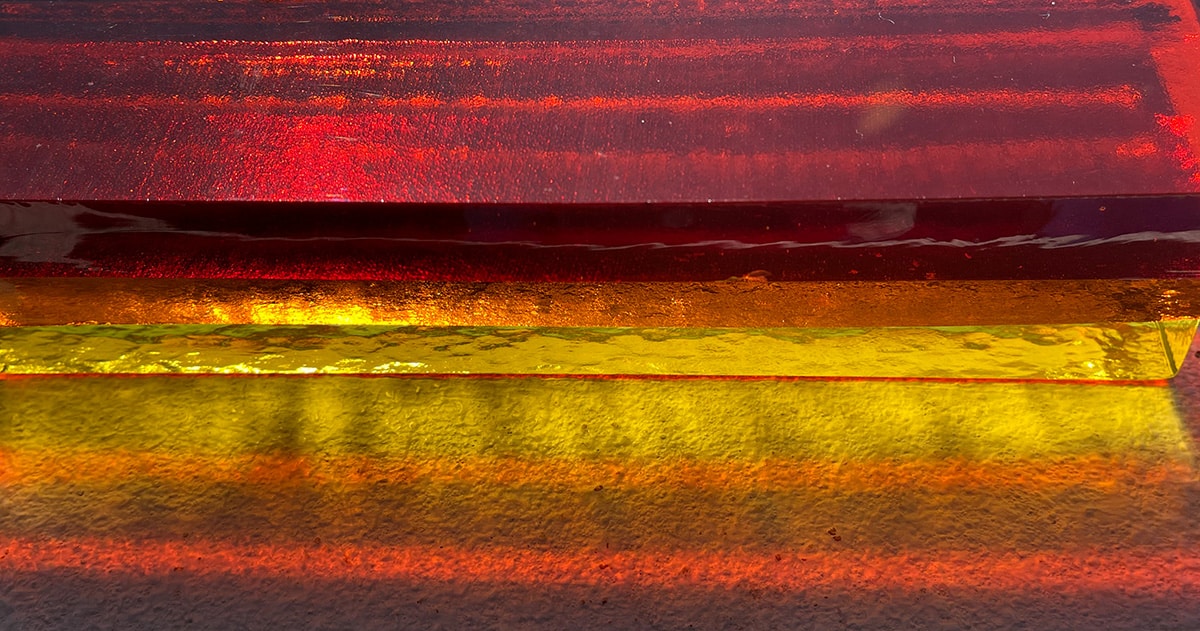

Bullseye’s red, orange, and yellow-hued glass styles contain the element, cadmium, which tends to be more sensitive to heatwork than other colorants.

This document explores how to work successfully with Bullseye’s cadmium-bearing glass styles.

Heatwork within Bullseye’s Tested-Compatible Range

Bullseye tests all cadmium-bearing glasses within its fusible (Grade-F) glass styles to guarantee they will withstand up to three firings at 1500 °F (815 °C) with 15-minute soaks before annealing. Within that tested compatible, triple fired range, you can fuse these glasses successfully without giving it a second thought.

Heatwork Beyond The Guaranteed Range

Many of our glass styles can withstand soaks longer than 15 minutes and far more than three firings. Artists and makers within our community do so all the time with wonderful results. But when venturing beyond Bullseye’s tested heatwork parameters, the only way to ensure consistent success is to conduct your own testing.

If your firings take the glass outside the parameters of our test for compatibility, you’ll want to test all the glasses you intend to use through all the firing schedules you intend to

use (basic steps below). This is especially true when using cadmium-bearing glasses. Generally speaking, these are more prone to shifts in color and compatibility than other glass styles. So before firing beyond tested limits, it is helpful to familiarize yourself with our cadmium-bearing

glasses (list on the reverse page) and to keep in mind a simple guideline:

When firing any glass beyond the tested compatible range, it is essential to conduct test—and this is especially true when using cadmium-bearing glass(es).

Testing for Specific Conditions

- Determine all glass styles to be used in your project.

- Determine precise firing schedules for the project’s full range of heatwork.

- Make sure test pieces share the same production date as the glass to be used for your project.

- Create test samples for each glass style/production date.

- Fire the samples using the project’s intended firing schedules and full range of heatwork.

- Observe what works, what doesn’t, and take meticulous notes.

- If the transparent cadmium glass(es) that you test opalize, that’s a sign that they are also shifting in compatibility characteristics, and you are advised to change the process or use glass(es) from a different production date.

Tips for Minimizing Overall Heatwork

- Whenever possible, avoid longer bubble squeeze holds. (Shorten or omit them as your project allows.)

- Add cadmium-bearing styles in later firings.

Download the article for a full list of cadmium-bearing styles.