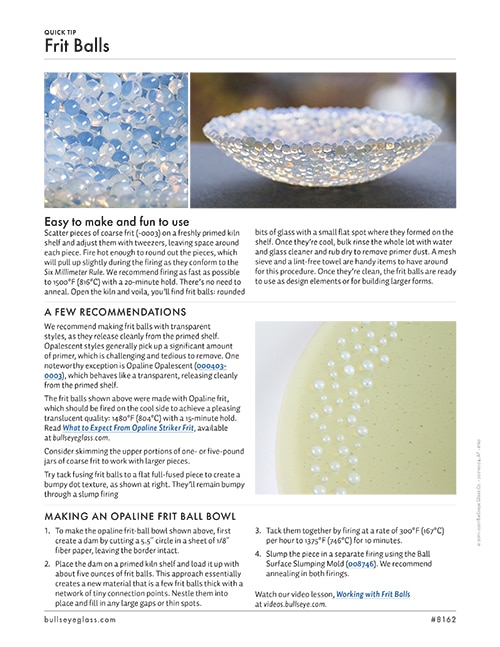

Easy to make and fun to use.

Scatter pieces of coarse frit (-0003) on a freshly primed kiln shelf and adjust them with tweezers, leaving space around each piece. Fire hot enough to round out the pieces, which will pull up slightly during the firing as they conform to the Six Millimeter Rule. We recommend firing as fast as possible to 1500°F (816°C) with a 20-minute hold. There’s no need to anneal.

Open the kiln and voila, you’ll find frit balls: rounded bits of glass with a small flat spot where they formed on the shelf. Once they’re cool, bulk rinse the whole lot with water and glass cleaner and rub dry to remove primer dust. A mesh sieve and a lint-free towel are handy items to have around for this procedure. Once they’re clean, the frit balls are ready to use as design elements or for building larger forms.

A Few recommendations

We recommend making frit balls with transparent styles, as they release cleanly from the primed shelf. Opalescent styles generally pick up a significant amount of primer, which is challenging and tedious to remove. One noteworthy exception is Opaline Opal (000403-0003), which behaves like a transparent, releasing cleanly from the primed shelf.

The frit balls shown above were made with Opaline frit, which should be fired on the cool side to achieve a pleasing translucent quality: 1480°F (804°C) with a 15-minute hold. Read What to Expect From Opaline Striker Frit, available at bullseyeglass.com.

Consider skimming the upper portions of one- or five-pound jars of coarse frit to work with larger pieces.

Try tack fusing frit balls to a flat full-fused piece to create a

bumpy dot texture, as shown at right. They’ll remain bumpy through a slump firing.

Making an Opaline Frit Bowl

- To make the opaline frit-ball bowl shown above, first

create a dam by cutting a 5.5˝ circle in a sheet of 1/8˝

fiber paper, leaving the border intact. - Place the dam on a primed kiln shelf and load it up with about five ounces of frit balls. This approach essentially creates a new material that is a few frit balls thick with a network of tiny connection points. Nestle them into place and fill in any large gaps or thin spots.

- Tack them together by firing at a rate of 300°F (167°C) per hour to 1375°F (746°C) for 10 minutes.

- Slump the piece in a separate firing using the Ball Surface Slumping Mold (008746). We recommend annealing in both firings.

Watch our video lesson, Working with Frit Balls at videos.bullseye.com.