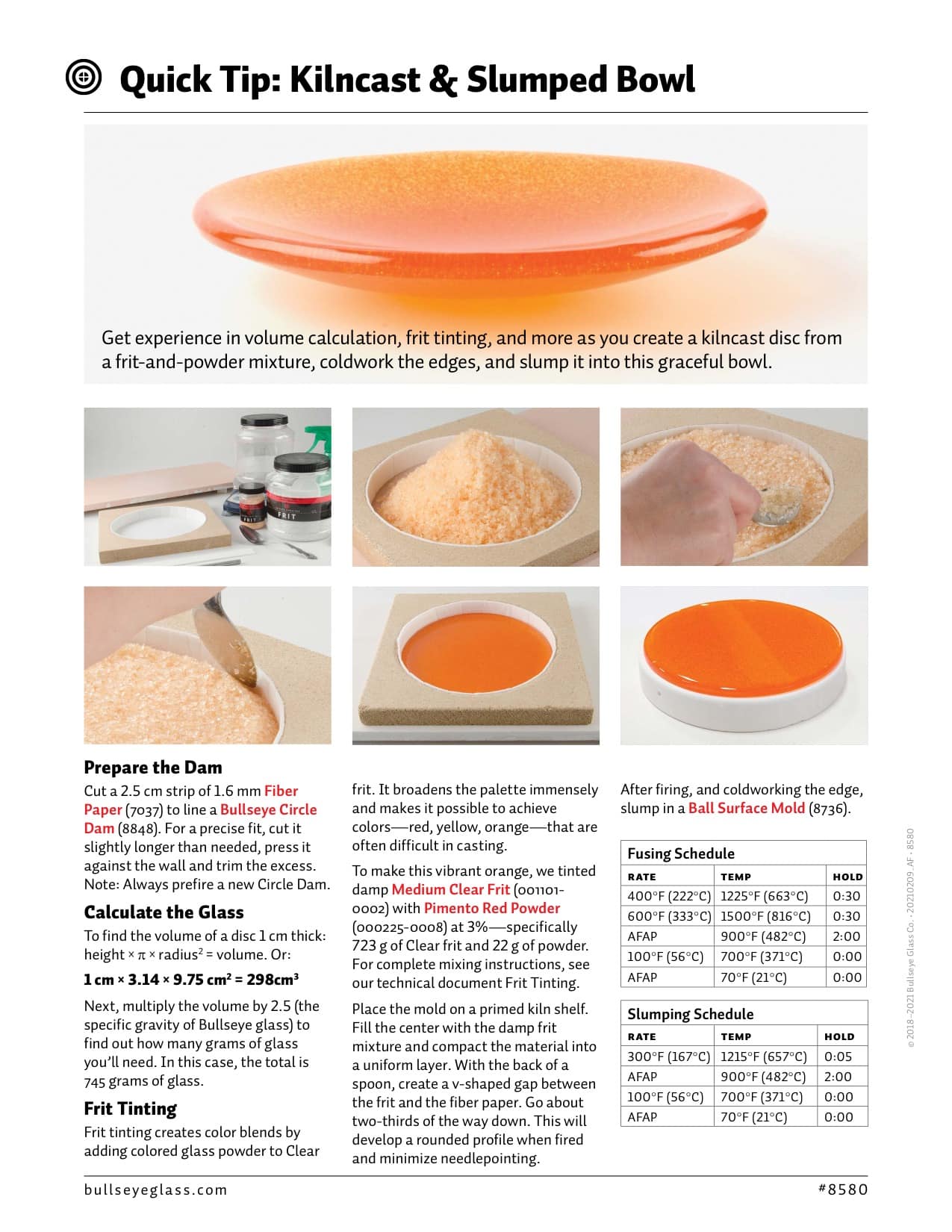

Get experience in volume calculation, frit tinting, and more as you create a kilncast disc from a frit and powder mixture, coldwork the edges, and slump it into a graceful bowl.

Prepare the Dam

Cut a 2.5 cm strip of 1.6 mm Fiber Paper (007037) to line a Bullseye

Circle Dam (008848). For a precise fit, cut it slightly longer than needed, press it against the wall and trim the excess. Note: Always prefire a new Circle Dam..

Calculate the Glass

To find the volume of a disc 1 cm thick: height × π × radius squared = volume. Or:

1 cm × 3.14 × 9.75 cm squared = 298 cm cubed

Next, multiply the volume by 2.5 (the specific gravity of Bullseye glass) to find out how many grams of glass you’ll need. In this case, the total is 745 grams of glass.

Frit Tinting

Frit tinting creates color blends by adding colored glass powder to Clear frit. It broadens the palette immensely and makes it possible to achieve colors—red, yellow, orange—that are often difficult in casting.

To make this vibrant orange, we tinted damp Medium Clear Frit (001101-0002) with Pimento Red Powder (000225-0008) at 3%—specifically 723 g of Clear frit and 22 g of powder. For complete mixing instructions, see our technical document Frit Tinting.

Place the mold on a primed kiln shelf. Fill the center with the damp frit mixture and compact the material into a uniform layer. With the back of a spoon, create a v-shaped gap between the frit and the fiber paper. Go about two-thirds of the way down. This will develop a rounded profile when fired and minimize needlepointing. After firing, and coldworking the edge, slump in a Ball Surface Mold (008736).