Unleash Your Unlimited Forms

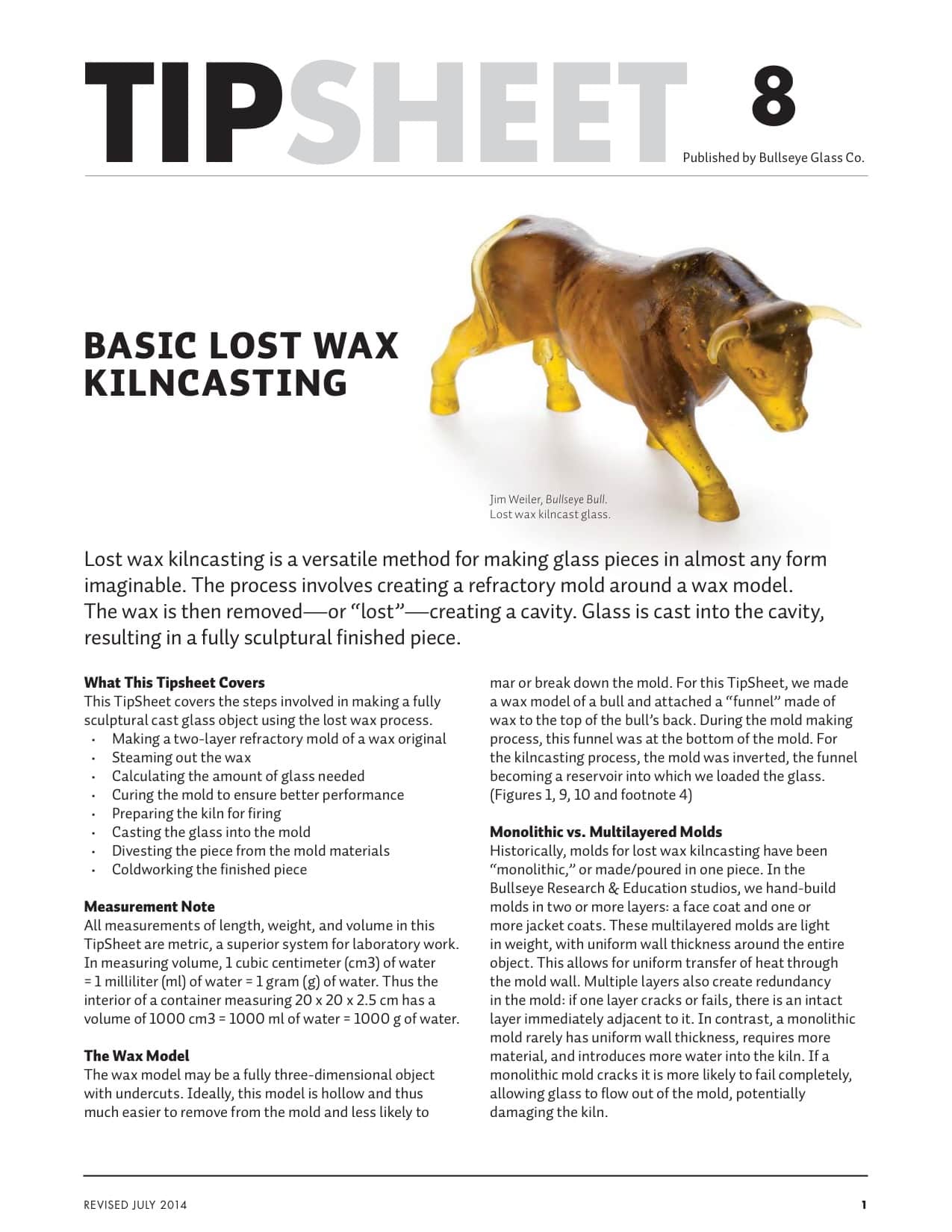

Lost wax kilncasting is a versatile method for making glass pieces in almost any form imaginable. The process involves creating a refractory mold around a wax model. The wax is then removed—or “lost”—creating a cavity. Glass is cast into the cavity, resulting in a fully sculptural finished piece.

This TipSheet covers the steps involved in making a fully sculptural cast glass object using the lost wax process.

• Making a two-layer refractory mold of a wax original

• Steaming out the wax

• Calculating the amount of glass needed

• Curing the mold to ensure better performance

• Preparing the kiln for firing

• Casting the glass into the mold

• Divesting the piece from the mold materials

• Coldworking the finished piece

Measurement Note

All measurements of length, weight, and volume in this TipSheet are metric, a superior system for laboratory work. In measuring volume, 1 cubic centimeter (cm3) of water = 1 milliliter (ml) of water = 1 gram (g) of water. Thus the interior of a container measuring 20 x 20 x 2.5 cm has a volume of 1000 cm3 = 1000 ml of water = 1000 g of water.

The Wax Model

The wax model may be a fully three-dimensional object with undercuts. Ideally, this model is hollow and thus much easier to remove from the mold and less likely to mar or break down the mold. For this TipSheet, we made a wax model of a bull and attached a “funnel” made of wax to the top of the bull’s back. During the mold making process, this funnel was at the bottom of the mold. For the kilncasting process, the mold was inverted, the funnel becoming a reservoir into which we loaded the glass…