Blog

-

Too Cool for School

|

Being named The Coolest Thing Made in Oregon for 2025 by Oregon Business & Industry could have given us all fat heads. In the majestic auditorium of the Portland Art Museum—amidst über-impressive competition like Daimler Trucks and Tillamook Cheese—Jim, Ted, Sam, Mary Kay, and I sat shell-shocked as Dan accepted the trophy from the president of Oregon […]

Latest Posts:

-

Autumn palettes in Bullseye glass, 6-9

Autumn: a word derived from “harvest,” when the summer sun has finished saturating the earth and the land offers up…

-

Winter palettes in Bullseye glass, 7-9

Winter shades span a dramatic range, from hot hearth reds and woolen whites to deep icy azures and forest brown.…

-

Summer palettes in Bullseye glass, 1-3

Ah, summer. At its best, isn’t it a vibrant palette of sensations? To help you explore and express that sparkling…

-

Revolutions, Roots, and Rings

When Dijenaire Frazier visited Bullseye for a tour in 2013, he mainly saw one thing: pure potential. Even though he’d…

-

Pop Portraits’ Wood Stand

For many years, Bullseye has taught various ways to transfer images into colored glass through screen-printing techniques adapted to make…

-

Bullseye Core Values + GMa Judy on Tik Tok

Judy Tuwaletstiwa and Caleb Sohigian recently joined Ted Sawyer for a residency at Bullseye Glass. Over five days, the trio…

-

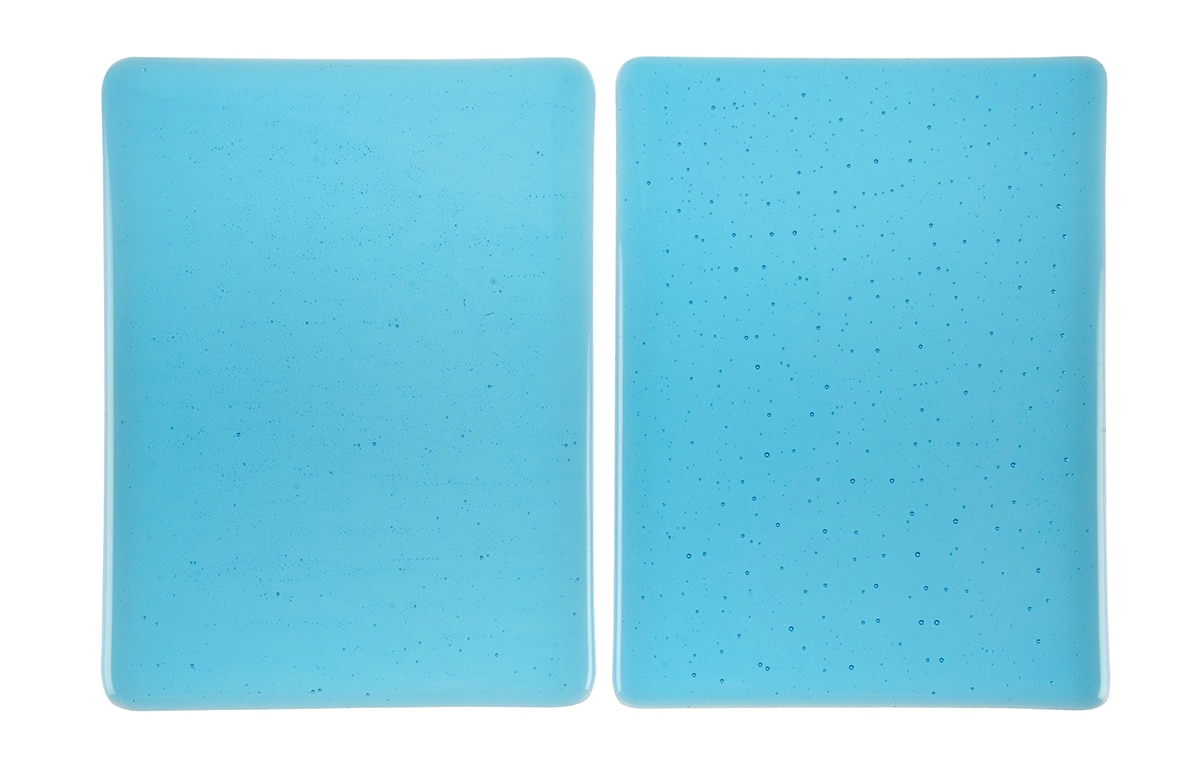

Powder Power! Video Quick Tip

Learn the secret to minimizing large bubbles when fusing sheet glass to create smooth, flat fused glass.

-

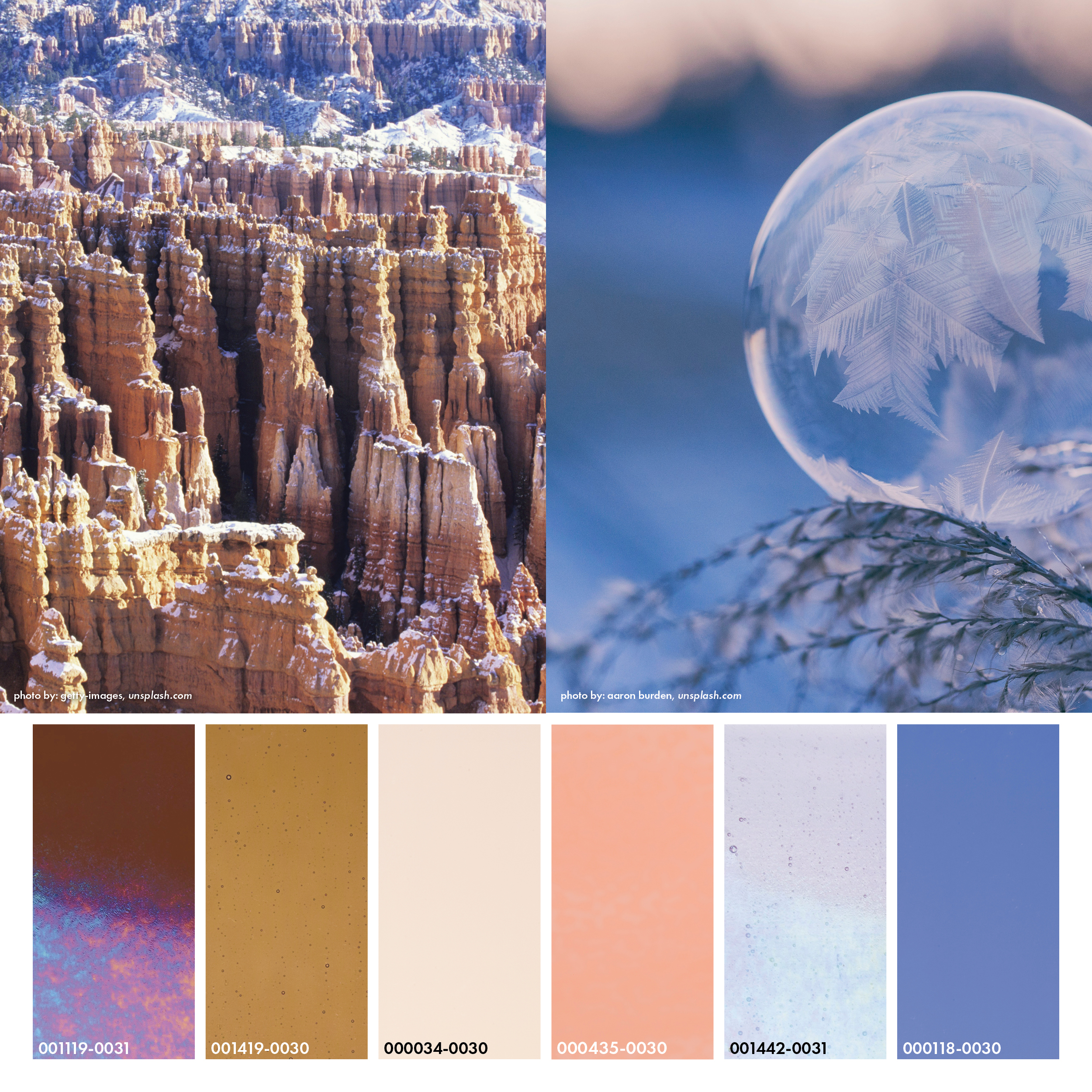

Winter palettes in Bullseye glass, 4-6

More palettes — this time wintry — from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry.…

-

Winter palettes in Bullseye glass, 1-3

More palettes — this time wintry — from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry.…

-

Quagliata Book Signing & Retrospective

Book Signing at Bullseye Los Angeles and Judson Studios On Saturday, October 25, during a week of special events celebrating…

-

Autumn palettes in Bullseye glass, 4-5

Here is more inspiration for fall palettes from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry.…

-

Autumn palettes in Bullseye glass, 1-3

One of the simplest ways to spark inspiration is to play with likenesses—rhymes, chords, palettes. So here are a few…

-

Snowflake Stations

Make a glass snowflake or two! It’s an annual tradition for many in the Bullseye community. No matter your experience…

-

Working Glass 2024

Bullseye employees do a lot with Bullseye glass: they melt it, roll it, sell it, package it, ship it, and…

-

Origins: The Bullseye Glass Story

In this one-hour video, you’ll meet many of the merry pranksters, intrepid artists, technical wizards, and colorful makers who played…